THE INNOVATIVE CHOICE FOR AN EVOLVED BUILDING SITE

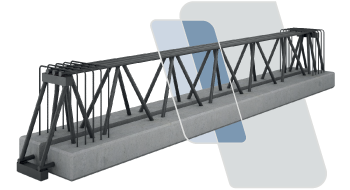

The MTR® System is the most reliable system in the field of steel-concrete composite structures. Innovative for the morphology, algorithm and calculation software, the MTR® System includes three typologies of trussed beams and is used to build horizontal structures for any type of construction.

WHAT IS THE MTR® SYSTEM

The MTR® System includes three typologies of trussed beams and the related calculation system for the design.

MTR® A BEAM

Self-supporting during deck assembly and casting, with steel bottom plate.

MTR® T BEAM

Requires formwork and shoring during deck assembly and casting, without bottom plate and completely embedded in the cast in-situ concrete.

MTR® C BEAM

Self-supporting during deck assembly and casting, with concrete bottom base.

CALCULATION APPLICATION

Software calculation application dedicated to the design of MTR® beams and implemented on the specific production process adopted by Metal.Ri.

Projects

A NEW CHALLENGE IS BORN FROM OUR EVERY MILESTONE

Over 20 years of activity in the field of steel-concrete composite structures, and millions of square metres of work completed in all construction sectors, from residential to commercial, from industrial to leisure and hospitality buildings.

PRE- AND POST-SALE CONSULTING

OUR VALUE ADDED

The structural design with the MTR® System fits any designation of use, such as residential, commercial, leisure, and industrial buildings. Contact us for a free technical consultation: an engineer of ours team will become your MTR® designer and will guide you in the choice of the MTR® element which suits your intervention, thanks to his/her expertise in the field of the design of composite structures.

The MTR® Designer will keep following you at all subsequent stages, from the modelling of the MTR® elements in your calculation programme, to the writing of the calculation report with the related drawings, to the visit on site for measurements, to the scheduling of the deliveries, to the technical assistance during the erection phases of MTR® System elements.

Every building can be designed and constructed exploiting the technical characteristics of a single MTR® beam typology or using more typologies at the same time. A wide range of possibilities to obtain the best result and satisfy any technical and economical requirement.

Find out the advantages of the MTR® System

News

THE FUTURE IS NOW

MTR® System at Futurebuild London

Metal.Ri are attending the Futurebuild 2022, the most important exhibition in Great Britain focused on eco-building. "Net zero" pioneer, Futurebuild aims to show new techniques, solutions and new building materials, concerning the themes of sustainability and energy...

The new church of San Leopoldo Mandic built with modern construction systems

The new church of San Leopoldo Mandic built with modern construction systems In recent years, one of the projects in which the MTR® System has been used is the construction of the new church of San Leopoldo Mandicin Massafra, in a rapidly expanding urban area. The new...

The MTR® System for the construction of an apartment complex of large numbers

Metal.Ri was responsible for the structural calculation and supply of MTR® beams for the entire residential complex, one of the largest in Bari.